Epoxy putty is a two-part adhesive that consists of a resin and a hardener. When these two components are mixed together, a chemical reaction known as polymerization occurs, creating a strong and durable bond. This versatile compound can be used to repair, patch, and fill almost anything, from metal and wood to ceramic and plastic.

Properties and characteristics of epoxy putty

Epoxy putty possesses several properties and characteristics that make it an exceptional choice for repair and bonding applications. Some of the key properties of epoxy putty include:

1. High Strength: Epoxy putty is known for its exceptional strength and durability. Once cured, it forms a strong bond that can withstand heavy loads and resist cracking or breaking.

2. Adhesive Properties: Epoxy putty has excellent adhesive properties, allowing it to bond to a wide range of materials, including metals, wood and ceramics.

3. Versatility: Epoxy putty is incredibly versatile and can be used for various applications. It can be shaped, molded, or sculpted to fit different surfaces or fill gaps, making it suitable for repairing, patching, or filling almost anything.

4. Resistance to Temperature and Chemicals: Epoxy putty is resistant to high temperatures, making it suitable for applications that require heat resistance, such as automotive repairs. It is also resistant to chemicals, moisture, and other environmental factors, ensuring long-lasting performance.

5. Easy to Use: Epoxy putty is easy to work with, even for beginners. It can be mixed and applied using simple tools and techniques, allowing for precise and accurate application.

These properties make epoxy putty an ideal choice for a wide range of applications, from everyday repairs to more specialized projects.

Applications of epoxy putty

Epoxy putty finds extensive use in various industries and applications due to its versatility and exceptional properties. Some of the common applications of epoxy putty include:

1. Plumbing Repairs: Epoxy putty is often used to fix leaks, seal pipe joints, and repair cracks in plumbing systems. It can withstand water pressure and provide a long-lasting solution.

2. Automotive Fixes: Epoxy putty is commonly used in automotive repairs to fill holes, repair dents, and bond parts together. Its temperature resistance and strength make it suitable for engine repairs, exhaust system fixes, and bodywork.

3. Metal Repairs: Epoxy putty is widely used to repair metal surfaces, including rusted or corroded areas. It can be used to fill holes, reinforce weak spots, and restore the structural integrity of metal objects.

These are just a few examples of the countless applications of epoxy putty. Its versatility and reliability make it an indispensable tool in various industries and for a wide range of projects.

How to use epoxy putty

Using epoxy putty is a straightforward process, but it requires careful attention to detail to ensure the best results. Here is a step-by-step guide on how to use epoxy putty effectively:

1. Prepare the Surface: Before applying epoxy putty, ensure that the surface is clean, dry, and free from any grease, oil, or loose particles. This will help in achieving a strong bond and proper adhesion.

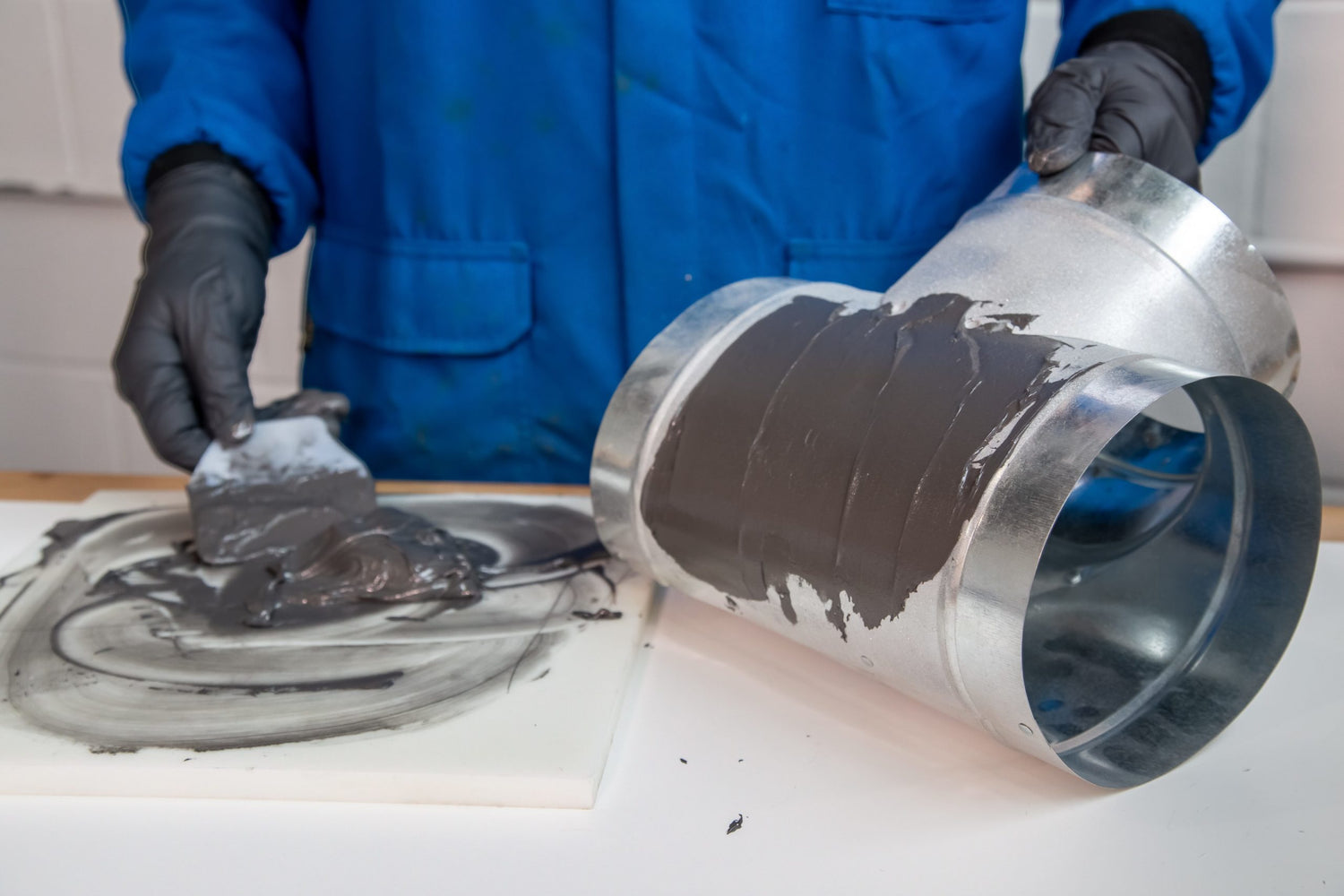

2. Mix the Components: Epoxy putty usually comes in two separate parts - the resin and the hardener. Follow the manufacturer's instructions to mix the components in the correct ratio. Use a clean mixing surface and tools to avoid contamination.

3. Blend Thoroughly: Once the components are mixed, blend them together thoroughly until you achieve a uniform consistency. This will ensure that the resin and hardener are evenly distributed, allowing for proper curing.

4. Apply the Putty: Use your hands or a putty knife to apply the epoxy putty to the desired area. Shape and mold it as needed, ensuring that it fills gaps or covers the damaged surface completely.

5. Smooth and Shape: After applying the putty, wet your fingers or the putty knife with water or a release agent to smoothen the surface and shape it to match the surrounding area.

6. Cure and Finish: Allow the epoxy putty to cure according to the manufacturer's instructions. Once fully cured, you can sand, paint, or finish the repaired area as desired.

Following these steps will help you achieve optimal results when working with epoxy putty. Remember to work efficiently as the putty can harden quickly, and always refer to the manufacturer's guidelines for specific instructions.

Devcon Epoxy Putty

Devcon epoxy putty products are widely recognized for their reliability and performance. Devcon has established its name as a leader in bonding metal. Their signature epoxy putties and two-part epoxy adhesives make it easy for customers to construct strong and durable metal structures. Industrial OEM markets, mining operations, coal-fired power plants, aggregate industries, and pulp & paper manufacturing rely on the good track record of Devcon metal epoxy products for successful production. Businesses in all of these industries have come to depend heavily on Devcon products for their success over the years.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.