Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films

Abstract

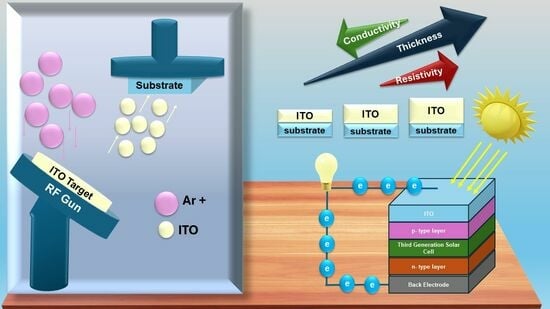

:1. Introduction

2. Materials and Methods

2.1. Preparation of ITO Samples Using PVD

2.2. Characterization Techniques

3. Results and Discussion

3.1. X-ray Diffraction Microscopy Measurements

3.2. Atomic Force Microscopy

3.3. Four-Point Probe

3.4. Scanning Electron Microscopy

3.5. Optical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tchenka, A.; Agdad, A.; Samba Vall, M.C.; Hnawi, S.K.; Narjis, A.; Nkhaili, L.; Ibnouelghazi, E.; Ech-Chamikh, E.; Zheludkevich, M. Effect of RF Sputtering Power and Deposition Time on Optical and Electrical Properties of Indium Tin Oxide Thin Film. Adv. Mater. Sci. Eng. 2021, 2021, 5556305. [Google Scholar] [CrossRef]

- Stadler, A. Transparent Conducting Oxides—An Up-to-Date Overview. Materials 2012, 5, 661–683. [Google Scholar] [CrossRef] [PubMed]

- Klaus, E. Magnetron sputtering of transparent conductive zinc oxide: Relation between the sputtering parameters and the electronic properties. J. Phys. D Appl. Phys. 2000, 33, R17. [Google Scholar]

- Klein, A.; Korber, C.; Wachau, A.; Sauberlich, F.; Gassenbauer, Y.; Harvey, S.P.; Proffit, D.E.; Mason, T.O. Transparent Conducting Oxides for Photovoltaics: Manipulation of Fermi Level, Work Function and Energy Band Alignment. Materials 2010, 3, 4892–4914. [Google Scholar] [CrossRef] [PubMed]

- Barman, B.; Swami, S.K.; Dutta, V. Fabrication of highly conducting ZnO/Ag/ZnO and AZO/Ag/AZO transparent conducting oxide layers using RF magnetron sputtering at room temperature. Mater. Sci. Semicond. Process. 2021, 129, 105801. [Google Scholar] [CrossRef]

- Noh, J.H.; Lee, S.; Kim, J.Y.; Lee, J.-K.; Han, H.S.; Cho, C.M.; Cho, I.S.; Jung, H.S.; Hong, K.S. Functional Multilayered Transparent Conducting Oxide Thin Films for Photovoltaic Devices. J. Phys. Chem. C 2009, 113, 1083–1087. [Google Scholar] [CrossRef]

- Hung, C.M.; Mai, C.L.; Wu, C.C.; Chen, B.H.; Lu, C.H.; Chu, C.C.; Wang, M.C.; Yang, S.D.; Chen, H.C.; Yeh, C.Y.; et al. Self-Assembled Monolayers of Bi-Functionalized Porphyrins: A Novel Class of Hole-Layer-Coordinating Perovskites and Indium Tin Oxide in Inverted Solar Cells. Angew. Chem. Int. Ed. Engl. 2023, 62, e202309831. [Google Scholar] [CrossRef]

- Dao, V.A.; Choi, H.; Heo, J.; Park, H.; Yoon, K.; Lee, Y.; Kim, Y.; Lakshminarayan, N.; Yi, J. rf-Magnetron sputtered ITO thin films for improved heterojunction solar cell applications. Curr. Appl. Phys. 2010, 10, S506–S509. [Google Scholar] [CrossRef]

- Sousa, M.G.; da Cunha, A.F. Optimization of low temperature RF-magnetron sputtering of indium tin oxide films for solar cell applications. Appl. Surf. Sci. 2019, 484, 257–264. [Google Scholar] [CrossRef]

- Kurdesau, F.; Khripunov, G.; da Cunha, A.F.; Kaelin, M.; Tiwari, A.N. Comparative study of ITO layers deposited by DC and RF magnetron sputtering at room temperature. J. Non-Cryst. Solids 2006, 352, 1466–1470. [Google Scholar] [CrossRef]

- Amalathas, A.P.; Alkaisi, M.M. Effects of film thickness and sputtering power on properties of ITO thin films deposited by RF magnetron sputtering without oxygen. J. Mater. Sci. Mater. Electron. 2016, 27, 11064–11071. [Google Scholar] [CrossRef]

- Yang, S.; Sun, B.; Liu, Y.; Zhu, J.; Song, J.; Hao, Z.; Zeng, X.; Zhao, X.; Shu, Y.; Chen, J.; et al. Effect of ITO target crystallinity on the properties of sputtering deposited ITO films. Ceram. Int. 2020, 46, 6342–6350. [Google Scholar] [CrossRef]

- Kudryashov, D.; Gudovskikh, A.; Zelentsov, K. Low temperature growth of ITO transparent conductive oxide layers in oxygen-free environment by RF magnetron sputtering. J. Phys. Conf. Ser. 2013, 461, 012021. [Google Scholar] [CrossRef]

- Tchenka, A.; Agdad, A.; Bousseta, M.; El Mouncharih, A.; Amiri, L.; Nkhaili, L.; Narjis, A.; Ibnouelghazi, E.; Ech-Chamikh, E.M. Effect of vacuum annealing and position of metal Cu on structural, optical, electrical and thermoelectrical properties of ITO/Cu/ITO multilayers prepared by RF sputtering. Opt. Mater. 2022, 131, 112634. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Sabah, F.A.; Abdulgafour, H.I.; Alsadig, A.; Sulieman, A.; Alkhoaryef, M. The effect of post annealing temperature on grain size of indium-tin-oxide for optical and electrical properties improvement. Results Phys. 2019, 13, 102159. [Google Scholar] [CrossRef]

- Gupta, L.; Mansingh, A.; Srivastava, P.K. Band gap narrowing and the band structure of tin-doped indium oxide films. Thin Solid Film. 1989, 176, 33–44. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, Y.; Ma, H.; Wu, Y.; Chen, M.; Wang, M.; Zhang, W.; Peng, Y.; Leng, Y.; Cao, Z.; et al. Broad-Band Ultrafast All-Optical Switching Based on Enhanced Nonlinear Absorption in Corrugated Indium Tin Oxide Films. ACS Nano 2022, 16, 12878–12888. [Google Scholar] [CrossRef] [PubMed]

- Thirumoorthi, M.; Thomas Joseph Prakash, J. Structure, optical and electrical properties of indium tin oxide ultra thin films prepared by jet nebulizer spray pyrolysis technique. J. Asian Ceram. Soc. 2018, 4, 124–132. [Google Scholar] [CrossRef]

- Xu, Y.; Wan, G.; Ma, L.; Zhang, Y.; Su, Y.; Liu, D.; Wang, G. Indium tin oxide as a dual-band compatible stealth material with low infrared emissivity and strong microwave absorption. J. Mater. Chem. C 2023, 11, 1754–1763. [Google Scholar] [CrossRef]

- Kim, J.H.; Jeon, K.A.; Kim, G.H.; Lee, S.Y. Electrical, structural, and optical properties of ITO thin films prepared at room temperature by pulsed laser deposition. Appl. Surf. Sci. 2006, 252, 4834–4837. [Google Scholar] [CrossRef]

- Izumi, H.; Ishihara, T.; Yoshioka, H.; Motoyama, M. Electrical properties of crystalline ITO films prepared at room temperature by pulsed laser deposition on plastic substrates. Thin Solid Film. 2002, 411, 32–35. [Google Scholar] [CrossRef]

- Li, J.; Jiang, L.; Chen, M.; Li, X.; Wei, Y.; Ma, Y.; Fu, Z.; Yan, Y. Structure and physical properties evolution of ITO film during amorphous-crystalline transition using a highly effective annealing technique. Ceram. Int. 2019, 45, 16214–16225. [Google Scholar] [CrossRef]

- Jung, S.K.; Kim, M.C.; Sohn, S.H.; Park, D.K.; Lee, S.H.; Park, L.S. Properties of Indium Tin Oxide on Polymer Films Deposited by Low-Frequency Magnetron Sputtering Method. Mol. Cryst. Liq. Cryst. 2006, 459, 167–177. [Google Scholar] [CrossRef]

- Xu, M.; Hu, S.; Peng, C.; Jing, B.; Chen, L.; Li, X.; Zhang, J. High-Performance Full-Solution-Processed Oxide Thin-Film Transistor Arrays Fabricated by Ultrafast Scanning Diode Laser. Adv. Mater. Interfaces 2022, 9, 2200976. [Google Scholar] [CrossRef]

- Carvalho, R.M.; Santos, L.; Bastos, M.; Costa, J.C.S. Carbon-Induced Changes in the Morphology and Wetting Behavior of Ionic Liquids on the Mesoscale. Langmuir 2024, 40, 3949–3961. [Google Scholar] [CrossRef] [PubMed]

- Tak, Y.-H.; Kim, K.-B.; Park, H.-G.; Lee, K.-H.; Lee, J.-R. Criteria for ITO (indium–tin-oxide) thin film as the bottom electrode of an organic light emitting diode. Thin Solid Film. 2002, 411, 12–16. [Google Scholar] [CrossRef]

- Raoufi, D.; Hosseinpanahi, F. The effect of film thickness on surface morphology of ITO thin films. J. Theor. Appl. Phys. 2013, 7, 21. [Google Scholar] [CrossRef]

- Kavei, G.; Zare, Y.; Mohammadi Gheidari, A. Evaluation of surface roughness and nanostructure of indium tin oxide (ITO) films by atomic force microscopy. Scanning 2008, 30, 232–239. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Diao, X.; Xu, H.; Gu, B.; Wang, T. Thickness dependence of structural, electrical and optical properties of indium tin oxide (ITO) films deposited on PET substrates. Appl. Surf. Sci. 2008, 254, 3504–3508. [Google Scholar] [CrossRef]

- Mizuhashi, M. Electrical properties of vacuum-deposited indium oxide and indium tin oxide films. Thin Solid Film. 1980, 70, 91–100. [Google Scholar] [CrossRef]

- Li, H.; Yang, Y.; Liang, X.; Zhang, W.; Cao, L.; Wu, C.; Zeng, Z.; Wang, L. Effect of annealing temperature and time on the microstructure, mechanical properties and conductivity of cold-rolled explosive Cu/Al composite sheets. Mater. Res. Express 2020, 7, 106502. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Hultåker, A. Transparent and conducting ITO films: New developments and applications. Thin Solid Film. 2002, 411, 1–5. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W.; Li, R.; Zhang, Y.; Xu, G.; Cheng, H. Fabrication of highly transparent and conductive indium-tin oxide thin films with a high figure of merit via solution processing. Langmuir 2013, 29, 13836–13842. [Google Scholar] [CrossRef]

- Ederth, J.; Heszler, P.; Hultåker, A.; Niklasson, G.A.; Granqvist, C.G. Indium tin oxide films made from nanoparticles: Models for the optical and electrical properties. Thin Solid Film. 2003, 445, 199–206. [Google Scholar] [CrossRef]

- Haschke, J.; Lemerle, R.; Aissa, B.; Abdallah, A.A.; Kivambe, M.M.; Boccard, M.; Ballif, C. Annealing of Silicon Heterojunction Solar Cells: Interplay of Solar Cell and Indium Tin Oxide Properties. IEEE J. Photovolt. 2019, 9, 1202–1207. [Google Scholar] [CrossRef]

- Gulen, M.; Yildirim, G.; Bal, S.; Varilci, A.; Belenli, I.; Oz, M. Role of annealing temperature on microstructural and electro-optical properties of ITO films produced by sputtering. J. Mater. Sci. Mater. Electron. 2012, 24, 467–474. [Google Scholar] [CrossRef]

- Krasilnikova Sytchkova, A.; Grilli, M.L.; Boycheva, S.; Piegari, A. Optical, electrical, structural and microstructural characteristics of rf sputtered ITO films developed for art protection coatings. Appl. Phys. A 2007, 89, 63–72. [Google Scholar] [CrossRef]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. J. Theor. Appl. Phys. 2015, 9, 285–290. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Vickraman, P.; Jayachandran, M.; Sanjeeviraja, C. Structural and optical properties of indium tin oxide (ITO) thin films with different compositions prepared by electron beam evaporation. Vacuum 2010, 84, 864–869. [Google Scholar] [CrossRef]

- Salehi, A. The effects of deposition rate and substrate temperature of ITO thin films on electrical and optical properties. Thin Solid Film. 1998, 324, 214–218. [Google Scholar] [CrossRef]

- Farhan, M.S.; Zalnezhad, E.; Bushroa, A.R.; Sarhan, A.A.D. Electrical and optical properties of indium-tin oxide (ITO) films by ion-assisted deposition (IAD) at room temperature. Int. J. Precis. Eng. Manuf. 2013, 14, 1465–1469. [Google Scholar] [CrossRef]

- Ahmed, M.; Bakry, A.; Qasem, A.; Dalir, H. The main role of thermal annealing in controlling the structural and optical properties of ITO thin film layer. Opt. Mater. 2021, 113, 110866. [Google Scholar] [CrossRef]

- van Dam, D.; van Hoof, N.J.; Cui, Y.; van Veldhoven, P.J.; Bakkers, E.P.; Gomez Rivas, J.; Haverkort, J.E. High-Efficiency Nanowire Solar Cells with Omnidirectionally Enhanced Absorption Due to Self-Aligned Indium-Tin-Oxide Mie Scatterers. ACS Nano 2016, 10, 11414–11419. [Google Scholar] [CrossRef] [PubMed]

- Furube, A.; Yoshinaga, T.; Kanehara, M.; Eguchi, M.; Teranishi, T. Electric-field enhancement inducing near-infrared two-photon absorption in an indium-tin oxide nanoparticle film. Angew. Chem. Int. Ed. Engl. 2012, 51, 2640–2642. [Google Scholar] [CrossRef] [PubMed]

- Azani, M.R.; Hassanpour, A.; Torres, T. Benefits, Problems, and Solutions of Silver Nanowire Transparent Conductive Electrodes in Indium Tin Oxide (ITO)-Free Flexible Solar Cells. Adv. Energy Mater. 2020, 10, 2002536. [Google Scholar] [CrossRef]

- Buchholz, D.B.; Proffit, D.E.; Wisser, M.D.; Mason, T.O.; Chang, R.P.H. Electrical and band-gap properties of amorphous zinc–indium–tin oxide thin films. Prog. Nat. Sci. Mater. Int. 2012, 22, 1–6. [Google Scholar] [CrossRef]

- Franzen, S. Surface Plasmon Polaritons and Screened Plasma Absorption in Indium Tin Oxide Compared to Silver and Gold. J. Phys. Chem. C 2008, 112, 6027–6032. [Google Scholar] [CrossRef]

- Dolgonos, A.; Mason, T.O.; Poeppelmeier, K.R. Direct optical band gap measurement in polycrystalline semiconductors: A critical look at the Tauc method. J. Solid State Chem. 2016, 240, 43–48. [Google Scholar] [CrossRef]

- Senol, S.D.; Senol, A.; Ozturk, O.; Erdem, M. Effect of annealing time on the structural, optical and electrical characteristics of DC sputtered ITO thin films. J. Mater. Sci. Mater. Electron. 2014, 25, 4992–4999. [Google Scholar] [CrossRef]

- Costa, J.C.S.; Taveira, R.J.S.; Lima, C.F.R.A.C.; Mendes, A.; Santos, L.M. Optical band gaps of organic semiconductor materials. Opt. Mater. 2016, 58, 51–60. [Google Scholar] [CrossRef]

- Souri, D.; Tahan, Z.E. A new method for the determination of optical band gap and the nature of optical transitions in semiconductors. Appl. Phys. B 2015, 119, 273–279. [Google Scholar] [CrossRef]

- Weijtens, C.H.L.; Van Loon, P.A.C. Influence of annealing on the optical properties of indium tin oxide. Thin Solid Film. 1991, 196, 1–10. [Google Scholar] [CrossRef]

- Kerkache, L.; Layadi, A.; Dogheche, E.; Rémiens, D. Physical properties of RF sputtered ITO thin films and annealing effect. J. Phys. D Appl. Phys. 2006, 39, 184–189. [Google Scholar] [CrossRef]

- Moriga, T.; Okamoto, T.; Hiruta, K.; Fujiwara, A.; Nakabayashi, I.; Tominaga, K. Structures and Physical Properties of Films Deposited by Simultaneous DC Sputtering of ZnO and In2O3 or ITO Targets. J. Solid State Chem. 2000, 155, 312–319. [Google Scholar] [CrossRef]

- Fallah, H.R.; Ghasemi, M.; Hassanzadeh, A.; Steki, H. The effect of annealing on structural, electrical and optical properties of nanostructured ITO films prepared by e-beam evaporation. Mater. Res. Bull. 2007, 42, 487–496. [Google Scholar] [CrossRef]

| Ref. | Year | Gas Type | Thickness (nm) | Annealing Temp (°C) | Electrical Properties | Transparency (%) | Band Gap (eV) | Morphological Properties |

|---|---|---|---|---|---|---|---|---|

| F. Kurdesau et al. [10] | 2006 | Argon–Oxygen | 300–500 | - | - | 80–85 | - | SEM: small-grained (10–20 nm) structure |

| Vinh Ai Dao et al. [8] | 2010 | Argon | 100 ± 5 | 100 | - | 87–90 | 3.67–3.83 | - |

| D Kudryashov et al. [13] | 2013 | Argon | ~100 | - | Resistivity: 5.4 × 10−4 Ω·cm | 80–90 | - | Smooth surface |

| A. P. Amalathas et al. [11] | 2016 | Argon | 75–225 | - | Average resistivity: 9.4 × 10−4 Ω·cm | Over 75 | 3.831–4.003 | AFM: surface roughness increased with thickness |

| Shumin Yang et al. [12] | 2020 | Oxygen | ~150 | 300 | - | 89.02–90.7 | 3.60–3.67 | - |

| This work | 2024 | Argon | 100 | 500 | Resistivity range: 1–2 × 10−4 Ω·cm | 86.16–89.0 | 3.44 | Low RMS roughness values |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alabdan, H.I.; Alsahli, F.M.; Bhandari, S.; Mallick, T. Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films. Nanomaterials 2024, 14, 565. https://doi.org/10.3390/nano14070565

Alabdan HI, Alsahli FM, Bhandari S, Mallick T. Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films. Nanomaterials. 2024; 14(7):565. https://doi.org/10.3390/nano14070565

Chicago/Turabian StyleAlabdan, Hessa I., Fahad M. Alsahli, Shubhranshu Bhandari, and Tapas Mallick. 2024. "Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films" Nanomaterials 14, no. 7: 565. https://doi.org/10.3390/nano14070565