Introduction

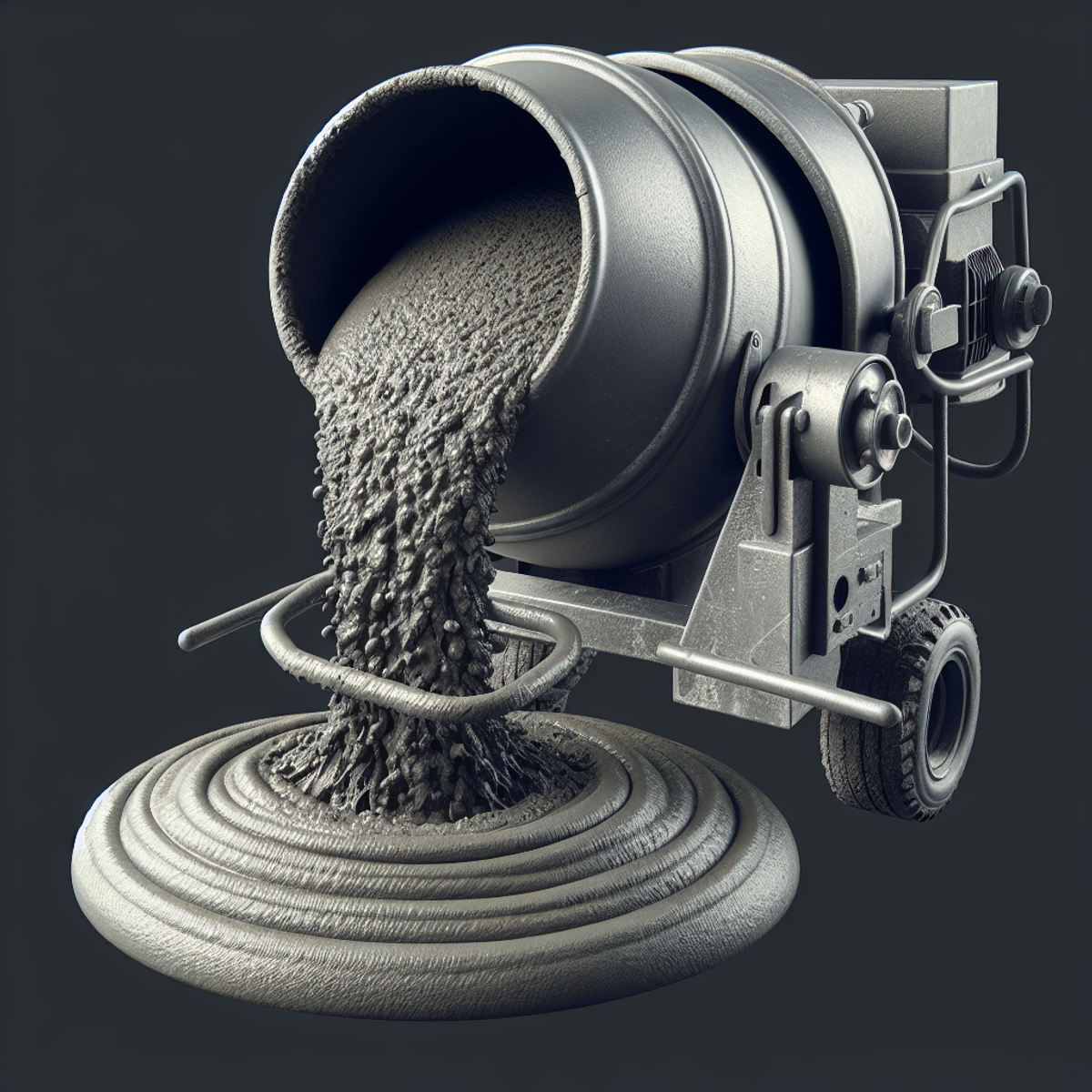

Delving into the world of concrete, the term ‘slump’ may not sound particularly glamorous, but it’s a fundamental concept that’s critical to the success of any construction project. Concrete slump is the measure that tells us about the consistency and workability of fresh concrete before it sets — essentially, it’s the flow factor.

Understanding the slump of concrete is akin to reading a vital sign for health; it’s an indicator that must be checked to ensure the resulting structure has the desired strength and durability. The significance of this seemingly simple test cannot be overstated; it’s a quick, initial diagnosis of the concrete’s condition, providing insights into its water content, workability, and overall quality.

In this article, we’ll navigate through the ins and outs of concrete slumps, highlighting their importance in construction and how they affect the integrity of a building. This essential knowledge not only supports the structure but also the confidence in the materials that make our environments safe and stable.

1. What is Concrete Slump?

- Definition and basic understanding

- Slump is the vertical displacement measured after a standard cone filled with concrete is lifted. It reflects the consistency and flow of the mix.

2. Significance of Concrete Slump

- Role in construction quality

- A critical indicator of water-to-cement ratio, affecting the concrete’s strength and durability once cured.

3. Measuring and Adjusting Concrete Slump

- How to measure and calculate

- Slump is measured by the slump test, where concrete is placed in a cone, removed, and the subsidence is measured.

We’ll explore these points in detail, ensuring that by the end of this article, the concept of ‘slump’ in concrete is not just understood but recognized as the crucial construction metric that it is. Whether you’re a seasoned professional or a curious newcomer, the knowledge of concrete slump is invaluable.

Defining Slump in Concrete

In the symphony of construction, ‘slump’ in concrete plays a pivotal role, akin to a maestro’s baton that directs the flow of a performance. It’s the measure of the concrete’s workability and consistency, crucial for ensuring that the mixture can be placed and finished with ease and precision.

The definition of slump in concrete is quite straightforward—it’s the vertical settling that occurs after a cone-shaped mold filled with concrete is lifted. This cone, known colloquially as the ‘slump cone,’ is filled with fresh concrete and then carefully removed—the degree to which the concrete slumps or collapses is then measured.

1. Understanding Slump Value

- What is the slump value in concrete?

- It’s the measure of the concrete’s fluidity or stiffness, indicating how easy it is to work with.

- Measuring the slump

- The slump value is the difference between the cone’s height and the height of the concrete after the cone is removed.

2. The Importance of Slump Measurement

- What does slump mean in concrete?

- It’s a quick field-test indicator of concrete’s current condition, hinting at its water content and mix proportions.

- Role of slump in workability

- A higher slump indicates a wetter mix, generally more workable, while a lower slump suggests a stiffer, less workable mix.

The slump test is a critical step in any construction process involving concrete. It ensures that the concrete mix is properly proportioned for the task at hand. Whether you’re pouring a foundation, a driveway, or a delicate architectural feature, understanding the slump value is paramount. The slump test, therefore, is not just a measure but a predictor of the success with which the concrete will take its final form.

The Significance of Slump in Ensuring Quality Concrete

The concrete slump is not just a number; it’s a testament to a building’s future strength and integrity. Ensuring the right slump is akin to setting the right foundation—it dictates the quality, strength, and longevity of the concrete, which, in turn, shapes the resilience of the structures we rely on daily.

In the realm of construction, achieving the ideal concrete slump is akin to finding the perfect pitch in music—it sets the stage for the performance of the material. A harmonious balance in the water-cement ratio, reflected in the slump, is the secret to concrete that not only holds strong but also stands the test of time.

1. Importance of Concrete Slump Test

- Ensuring workability

- The slump test’s findings are critical as they impact how easily concrete can be mixed, handled, and applied.

2. Slump’s Role in Concrete Quality

- Insight into water-cement ratio

- Slump provides a snapshot of this ratio, which is crucial for concrete’s final strength and durability.

3. Consistency and Performance

- Achieving consistency

- Consistent slump values lead to uniform quality across the concrete batch, which is vital for the structural integrity of a project.

4. The Interplay of Workability, Strength, and Durability

- How does a slump affect concrete?

- It directly impacts the concrete’s ability to be placed and compacted properly, which determines its strength and durability.

The proper application of the slump test, therefore, is a key quality control measure. It ensures that each batch of concrete poured is primed for performance, setting the stage for towers that are as durable as they are robust. In essence, a vigilant eye on slump is the silent guardian of a structure’s longevity.

Measuring and Interpreting Slump Values

Measuring slump in concrete is not just about gathering numbers—it’s about capturing the essence of the concrete’s current state, much like a snapshot captures a moment in time. The slump cone test is a straightforward yet crucial procedure that reveals much about the concrete’s workability and future performance.

This test is not unlike a tea ceremony; a specific method and order must be followed to ensure accuracy and reliability. It’s a simple yet profound ritual that speaks volumes about the concrete’s potential.

1. How to Conduct a Slump Test

- Using the slump cone

- The cone is filled with concrete in three layers, each compacted with a rod to remove air pockets.

- Measuring the slump

- After the cone is lifted, the slump value is the vertical distance the concrete slumps from the original height of the cone.

2. Interpreting Slump Values

- Reading the results

- A high slump value generally indicates high workability, which may be suitable for certain types of construction but could imply a high water content compromising strength.

- Understanding low values

- A low slump suggests a drier, less workable mix, potentially indicating a mix that’s more suited for structures requiring higher strength.

Understanding the nuances in these numbers allows construction professionals to adjust their mixes and techniques accordingly, ensuring that each pour is optimized for its intended purpose. Just as a musician interprets a piece of music, a skilled professional interprets slump values to create concrete that sings with strength and durability.

Factors Influencing Slump Loss in Concrete Mixtures

In the alchemy of concrete making, the consistency of the mix—indicated by slump—is influenced by various factors, each interplaying in a delicate balance. Due to the impact of external conditions and internal components, the consistency can change, almost as if it has a life of its own.

Just as the environment affects our well-being, temperature, humidity, and composition affect the health and workability of concrete. Each element plays a role in either preserving or reducing the slump, which in turn dictates how the concrete will perform.

1. The Impact of Water Content

- Hydration’s role

- Water is the lifeblood of concrete, but too much can weaken the structure, while too little can lead to poor workability.

2. The Role of Admixtures

- Chemical interactions

- Admixtures can enhance workability without increasing water content, but they must be carefully balanced to maintain slump.

3. Environmental Factors

- Weather’s influence

- Hot or dry conditions can speed up evaporation, causing slump loss, while cold can slow down the setting time and reduce slump loss.

4. Admixture and Temperature Interactions

- Complex reactions

- The interaction between chemical admixtures and temperature can either stabilize or destabilize the slump, requiring careful monitoring.

Navigating these factors is crucial for maintaining the desired slump throughout the concrete’s life—from mixing to placement to setting. It’s a dynamic challenge that demands both knowledge and flexibility. By understanding and managing these influences, professionals can ensure that the concrete maintains its desired workability, strength, and durability, ultimately shaping the structures that stand as a testament to human ingenuity.

Managing Slump Variations on Construction Sites

To control the concrete slump on a bustling construction site is to master the art of precision amid chaos. Ensuring that the concrete maintains its specified slump until it’s placed is crucial for the structural integrity and longevity of the project.

Regular checks and balances, much like the rhythm in a dance, are key to keeping the slump within the desired range. Through vigilant monitoring and skilled adjustments, one can navigate the variances that occur naturally throughout a pour.

1. Monitoring and Testing

- Regularly checking the slump

- Consistent testing ensures that the concrete remains within the project’s specified limits, maintaining quality and compliance.

2. Slump Adjustment Strategies

- Admixture usage

- Admixtures can be added to increase workability without compromising the water-cement ratio.

- Water adjustment

- Carefully measured amounts of water can be added to adjust the slump, but caution is needed to prevent weakening the mix.

3. Workforce Training

- Knowledge is power

- Educating site personnel on the importance of slump and how to manage it can prevent errors and ensure a quality build.

4. Methods for Slump Control

- Admixtures vs. Water

- The decision between admixtures and water additions depends on the desired outcome and existing conditions of the concrete.

By empowering site personnel with the knowledge and tools to manage concrete slumps effectively, you’re not just building structures; you’re building confidence in the quality and durability of the work being performed. Whether you’re adjusting with water or admixtures, the key is to do so with the precision and care that the craft of construction deserves. Through diligent management and control, concrete slump variations become less of an uncertainty and more of a controlled element within the art of building.

Preventing and Addressing Issues Related to Excessive or Low Slump

Just as a balanced diet is essential for good health, the right slump is crucial for the quality of concrete. Both excessive and low slumps can lead to a host of problems, affecting the integrity and longevity of concrete structures.

Problems with high or low-slump concrete are like ailments in the body of construction, each with its symptoms and remedies. Recognizing these issues early on can prevent long-term complications, ensuring the concrete’s strength and durability.

1. Addressing Excessive Slump

- Issues with high slump

- Can lead to segregation, where the aggregate separates from the cement paste, and bleeding, where water rises to the surface.

- Solutions

- Tighten control on the water-cement ratio and consider using admixtures that stabilize the mix.

2. Managing Low Slump

- Problems with low slump

- Can make the concrete difficult to work with and may lead to poor compaction and trapped air pockets.

- Remedies

- Utilize water-reducers or superplasticizers to improve workability without increasing water content.

3. Preventive Measures

- Mix design and placement techniques

- Employ a well-designed mix and meticulous placement and compaction techniques to maintain appropriate slump levels.

4. Overcoming Common Challenges

- Remedial actions

- Adjust mix designs or add modifiers as needed, and ensure proper curing practices are followed.

Understanding the science behind the slump is like understanding the ingredients of a recipe—it allows for a fine-tuned approach to creating the desired final product. By managing the factors that affect slumps, construction professionals can prevent the issues associated with high or low slumps, ensuring that the concrete not only meets design requirements but also stands up to the demands of its environment.

Conclusion

In conclusion, the journey through the nuances of concrete slump reveals its critical role in ensuring the quality, performance, and durability of concrete structures. This simple test speaks volumes about the workability and consistency of the mix, which are pivotal in the realm of construction.

Understanding and managing concrete slumps is not just a technicality—it’s an essential piece of the puzzle in achieving construction excellence. Whether you’re a master builder or a curious observer, recognizing the importance of slump is fundamental to appreciating the integrity of the built environment.

To encapsulate our discussion:

- Understanding Concrete Slump: It’s the cornerstone of quality in construction, influencing workability and strength.

- The Slump Test is a vital diagnostic tool that offers insights into concrete’s current state and potential performance.

- Managing Slump Variations: Mastery of this aspect ensures that concrete maintains its specified quality from pour to cure.

- Addressing Slump-Related Issues: Proactive measures and adjustments can mitigate the risks associated with high or low slump values.

By embracing the principles outlined in this guide, construction professionals can ensure that each mix of concrete is tailored to meet the demands of the project at hand, leading to structures that are not only built to last but also exemplify the highest standards of quality and performance. Understanding ‘slump’ in concrete is, therefore, not just about managing a material—it’s about shaping the future of our infrastructure with expertise and care.