An engine is a most vital part of all vehicles, which helps to run the vehicle. An engine consists of different components. The crankshaft and piston are the essential parts of reciprocating engines. Without these two vital parts, the reciprocating engines can’t work. The crank is known as the backbone of an internal combustion engine. This article explains the crankshaft working, construction, parts, and applications.

What is a Crankshaft?

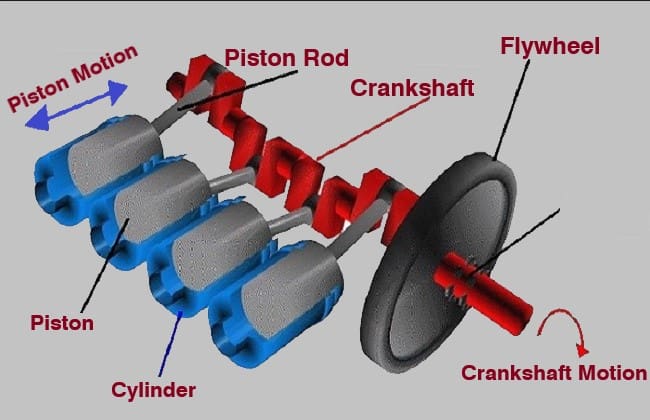

A crankshaft is a mechanical part that transforms the reciprocating movement of the piston into rotational motion and turns the vehicle wheels. It is connected to the piston through a connecting rod.

The main function of the crankshaft is to transform the piston’s linear motion into rotary motion and turns the vehicle wheels. It works according to the upward and downward movement of the piston.

Without a crank, a reciprocating engine can’t deliver the piston’s reciprocating motion to the drive shaft. In simple words, a reciprocating engine can’t move a vehicle without a crankshaft.

It works on the crank mechanism. The crankshaft is located inside the engine block. It has many crankpins and cranks. The engine connecting rod is connected to the crankshafts through these crankpins and cranks.

Different engines complete a power cycle in a different number of turns of the crankshaft. For example, a 2-stroke engine completes a power cycle after one revolution of the crankshaft, while a 4-stroke engine completes a power cycle after completing two revolutions of the crankshaft.

Crankshafts can be in welded, semi-integral, or one-piece structures. This part of the engine attaches the output section of the engine to the input section.

It acts as a link that delivers output power in the kind of rotational kinetic energy—the piston connects with the cranking center via a connecting rod. The cranking lever enables the piston to turn the crankshaft to produce power to move the vehicle.

Working of Crankshaft

A crankshaft works on the crank mechanism. A crank has multiple crankpins and cranks that are used to connect it with the connecting rods. It has a vibration damper that reduces the thrust on the crank.

A crankshaft of a 4-stroke engine works in the following way:

- As the engine piston moves from TDC to BDC (downward stroke), it transfers its motion to the crankshaft via a connecting rod.

- The crank further transforms the piston’s linear motion into rotary motion and transfers it to the camshaft.

- As the camshaft receives rotary motion, it opens the inlet valve, and the air-fuel mixture enters the combustion chamber.

- As the combustion chamber is filled with the air-fuel mixture, the piston moves upward (from BDC to TDC) and compresses the mixture. During this process, the camshaft closes both the inlet and exhaust valves. As the compression process completes, the first revolution of the crankshaft also completes.

- At the end of the compression process, the ignition process takes place.

- The heat released by the compressed mixture due to the ignition process forces the piston to move downward. This stroke is known as a Power Stroke. During this piston’s downward, the piston again transfers its reciprocating to connecting rod, which further sends it to the crankshaft.

- One end of the crank connects with the flywheel. As the crank receives the piston’s motion, it transfers this motion to the flywheel. The flywheel stores this motion and further drives the vehicle wheels.

- After the power stroke, the piston further moves downward for discharging the exhaust gases. During this process, the camshaft receives the piston’s motion by the crank and opens the exhaust valve while the inlet valve remains closed. The piston pushes the exhaust gases out of the combustion chamber.

- After the exhaust stroke, two revolutions of the crank are completed, and one power cycle of a 4-stroke engine also completes. After this, the whole cycle repeats.

For a better understanding, imagine your legs pedaling a bicycle. In this example, consider the pedals as connecting rods, and your legs are the pistons. As you paddle the piston, the reciprocating movement is converted to a rotary motion of the crankshaft.

Read More: Working of Connecting Rod?

Construction of Crankshaft

The crankshaft design varies according to the engine type, but maximum crankshafts contain multiple main bearing journals, counterweights, and crank throws. The counterweight assists in balancing the rotational forces, while the main bearing journals ensure the smooth rotation of the crankshaft within the engine block.

The following are the materials used for the construction of the crankshaft:

- Cast Iron

- Carbon Steel

- Vanadium Micro-alloyed Steel

- Forged Steel

The cranks can be assembled from various pieces or made in the form of a one-piece (monolithic). The monolithic type is the most commonly used crankshaft all over the world.

Some large and small internal combustion engines have assembled crankshafts. These shafts may also be cast in malleable iron, modular or ductile steel. The forging process has excellent strength. Therefore, the forging process is known as the preferred process for the construction of crankshafts.

Casting and Forging Process of Crank

Crankshafts can generally be forged from casts in ductile steels or by roll forging by using steel bars. Nowadays, maximum manufacturers use forged crankshafts because of their excellent inherent damping, compact design, and lightweight.

Vanadium micro-alloyed steel is mainly used for the forged crankshaft. This is because these steels can be air-cooled without further heat treatments except the bearing surface hardening once they have reached a high strength. It also has a lower alloy content which makes the material low-cost as compared to high-alloy steel.

Nowadays, only some engines use crankshafts made of cast iron for the cheap and low-power model, while the expensive and high-power models of engines use forged steel crankshafts.

Read More: Different Types of Engines

Parts of Crankshaft

The parts of the crankshaft are given below:

- Main Journal

- Crankshaft Pulley

- Oil Passways

- Balance Hole

- Counterweight

- Crankshaft Lubrication

1) Main Journal

The main bearing journal is attached to the engine block. All crankshaft journals are very hardened, rounded, and smooth. The main journal is settled in the saddle, where a replaceable bearing insert can be placed.

The bearing is softer compared to the main journals, and these can change when it wears. The bearing designs are used to capture a small volume of impurities (if any) to prevent the crankshafts from damage.

The main bearing cap screws onto the journal and tighten to the particular torque.

The journal of the engine runs over the oil film. This oil film pushes in the gap between the bearing and the journal via the crankshaft saddle’s holes and the linking holes of the bearing insert. If there are sufficient oil delivery and pressure, the bearings and journals will not come into contact.

Read Also: Different Types of Internal Combustion (IC) Engines

2) Connecting Rod Journal

The connecting rod journal is offset from the axis of rotation and connected to the larger end of the piston rod.

The connecting rod journal provides a bearing surface or pivot point for the big end of the connecting rod. In simple words, it acts as the point where the connecting rod makes a connection to the crankshaft.

It usually has a cylindrical, circular shape. It has a precise size to ensure a low-friction and smooth edge with the connecting rod bearing. The connecting rod bearing is a thin, replaceable metal shell that gives a lubricated and wear-resistant surface between the connecting rod journal and the connecting rod.

3) Crankshaft Lubrication

Metal-to-metal contact is an enemy of efficient engines. The engine moving parts require a proper supply of lubricant to work efficiently. The connecting rod journal and main journal both move on the oil film assembled on the bearing’s surface.

Lubricating the main journal bearings is easy. The oil passages from the engine block to each crankshaft seat and the corresponding holes in the bearing housing allow the engine oil to reach the journals.

The rod journal bearing requires the same lubrication, but it rotates at the off-center around the crankshaft. To supply these bearings with oil, the oil channel runs within the crankshaft by the main journals, diagonally by the web, and exits the hole in the connecting rod journal.

The grooves in the major rod bearings drain the oil under the effect of the rotating crankshaft centrifugal force and keep the oil pressed into the channel of the rod journal.

The gap between the bearing and the journal is the major cause of engine oil pressure. If the gap is too large, the oil will flow freely, and the pressure will not maintain.

If the gap is too small, the oil pressure increases, and the metals may come into contact with each other.

Read Also: Low Engine Oil Symptoms and Causes

4) Counterweights

A crankshaft is applied to a strong rotating force, and the mass moving down and up between the connecting rod and the piston applies a large force. The counterweight is used to balance these forces. These counterweights make the engine faster and quieter.

The crankshafts balance at the factory. During this process, the flywheel attaches, and the entire assembly rotates towards a machine that can measure the location of the flywheel imbalance.

The counterweight has a balance hole to lessen weight. If you need to add weight, make a hole first, then fill it with heavy metal. Repeat this process until the crankshaft comes in balance condition.

5) Thrust Washers

More than two or more thrust washers are installed at specific positions along the length of the crankshaft to prevent it from moving vertically.

These washers are positioned between the web’s machined surface and the crankshaft’s seat to maintain a small specified clearance and minimize the lateral movement available to the crankshaft. This distance that moves the shaft from one end to the other is known as the endplay, and the tolerance is quantified in the service manual.

Some types of engines form these washers as a component of the main journal bearing, while other engine types (usually older types) use distinct washers.

6) Main Oil Seal

The ends of the crankshaft extend outside the crankcase. So, you need to provide a way to prevent oil from seeping through these openings. This oil seeping problem controls through two main oil seals; one is on the front and the other on the rear or backside.

The rear main seal is located between the flywheel and the rear main journals. Usually, it is a synthetic rubber lip seal. This sealing ring is inserted into the groove between the oil pan and the engine block. This seal has a molded lip that pushes in contrast to the crankshaft through a spring known as a garter spring.

Read Also: Bad Oil Pan Symptoms and Causes

7) Crankshaft Pulley

The crankshaft pulley is also known as a crankshaft sheave or harmonic balance. It is a grooved, wheel-shaped unit that directly couples with the crank of the car. It links to other parts of your vehicle through the accessory belt.

What are the reasons of a damaged Crankshaft?

The most common reasons for the crankshaft break are given below:

- The crankshaft may break due to overloading through water hammer, abnormal combustion, etc.

- Defective shaft material can also damage the crankshaft

- An unexpected engine jam because of loose counterweight, gearbox failure, etc.

- The shaft’s mechanically damaged before fixing.

- Unnecessary rotation and vibration due to clutch failure, defective flywheel, or damaged vibration damper.

- Insufficient improvement work on the crankshaft bearings.

- Material damage because of earlier bearing failure and annealed bearing journals, etc.

- The bearing journal has become soft as a result of premature bearing failure or improper repair work (e.g., unnecessary regrinding).

- The commissioning of the engine did not correspond to the manufacturer’s instructions.

- Use of wrong bearing shell.

- The old bearing head bolts or improper torque are utilized.

- Too little lubricant during commissioning because the oil system is not pre-filled and pre-compressed.

- The bearing caps of the connecting rod/main bearing were mixed or fixed crooked.

- The crankcase bearing’s bore size inside the crankshaft was not inspected or repaired after damage.

- The oil filter, engine oil, and oil cooler have not been changed on time.

- If the bearing is damaged, the swarf that remains in the engine oil circuit can also cause the crankshaft to break.

Reasons for Crankshaft Unbalancing

The following are the significant reasons for crank unbalancing:

- The reciprocating motion of the piston inside the combustion chamber.

- Due to twist and torsion produced in the crankshaft.

- Crankcase fire or explosion

- Due to power stroke. Because after completion of a power stroke in the engine, the piston applies a jerk force on the crankshaft to rotate it more.

- Grounding of the ship

Read Also: Working of Camshaft

Camshaft Vs Crankshaft

The major difference between a crankshaft and a camshaft is given below:

| Crankshaft | Camshaft |

|---|---|

| It is constructed by the casting of steel or cast iron. | It is constructed by the casting of steel or cast iron. |

| Both 2-stroke and 4-stroke engines have this shaft. | It is constructed by the forging of alloy steel. |

| It is installed inside the cylinder | This shaft installs on the cylinder head. |

| A crankshaft gets motion from the piston via a connecting rod. | The camshaft gets motion or power by the connecting rod. |

| A crankshaft uses to transform the piston’s reciprocating movement into rotary motion. | A camshaft uses to close and open the suction valve and exhaust valve according to the movement of the piston. |

| The engine piston rotates it via a connecting rod. | The timing belt rotates the camshaft, which is connected to the crankshaft. |

| It has a high weight. | It has low weight. |

| A crankshaft has high cost than a camshaft. | A camshaft is cheap. |

| This shaft has an oil hole, crank web main journal bearing, and crankpin. | This shaft has integrated gear and cams. |

| In the case of a 4-stroke engine, it rotates two times to complete a power cycle. | In a 4-stroke engine, it rotates only one time to complete a working cycle. |

Applications of Crankshaft

- Automotive Industry: Crankshafts are most commonly used in different vehicle engines, including buses, cars, trucks, motorcycles, and other vehicles. Crankshafts are a major part of IC engines (both gasoline and diesel engines).

- Reciprocating Compressors: Crankshafts are most commonly used in reciprocating compressors and reciprocating pumps. It converts the piston’s reciprocating motion into rotary motion, which runs the compressor unit.

- Aerospace Industries: Crankshafts are also employed in some aircraft engines, especially in piston-driven engines employed in smaller aircraft. In these engines, the crankshaft converts the reciprocating motion of the piston into rotary motion, which runs the propeller.

- Marine Industry: They use as a vital component of marine engines used for boats, ships, and other watercraft.

- Agricultural Equipment: Crankshafts are used in different agricultural equipment, such as combines, harvesters, tractors, and other machines.

- Power Generation: This part of the engine is used in stationary engines, such as those employed in generators or power plants for electricity production.

- Locomotive Industry: They are also employed in locomotive engines, including the diesel-electric train. In locomotive engines, the crankshafts transform the reciprocating motion of the piston into rotary motion to run a generator used to drive the electric motor attached to the wheels.

- Industrial Machinery: They are most commonly employed in different industrial machines and equipment, including compressors, pumps, and other mechanical systems.

FAQ Section

Who invented crankshaft?

The crankshaft was invented by al-Jazari in 1206.

What are the types of crankshafts?

The crankshaft has the following major types:

- Billet crankshaft

- Cast crankshaft

- Forged crankshaft

- Solid single-piece shaft

- Fully built shaft

- Welded shafts

- Semi built shaft

Is there any type of engine that works without a crankshaft?

There are two types of engines

The reciprocating engines are designed in such a way that they can’t work without a piston and crankshaft. While a Wankel engine works with the help of a rotor, and doesn’t need a piston and crankshaft.

Does the crankshaft turn the camshaft?

The crankshaft is connected to the camshaft via a chain or timing gear. The crank transfers its motion to the camshaft via this timing gear. As the camshaft receives rotary motion from the crankshaft, it uses this motion to open and close the inlet and exhaust valves.

Which engine doesn't have a camshaft?

A two-stroke engine doesn’t have a camshaft. The only 4-stroke engine uses it to open and close the exhaust and inlet valves.

How to start a car with a bad crankshaft sensor?

Make sure the ignition is ON only when the engine light is ON, and other indications are minimal.

If your vehicle stops one or two times, or you face acceleration jerks after starting the vehicle, you can drive but need to take it to the workshop. If the problem is more serious, driving can cause serious engine damage, which can increase repair costs.

Therefore, if your car’s crankshaft sensor is damaged, you should replace or repair it as soon as possible for the excellent working of your engine.

A crankshaft works on which mechanism?

A crankshaft works on the crank mechanism.

How many crankshafts are in a v8 ?

Almost 99% of V8 engines have only one crankshaft.

What causes the crankshaft to go bad?

- Engine overheating

- Poor lubrication

- Contaminated engine oil

- Faulty timing belt

How to extend the service life of the Crankshaft?

- Proper maintenance of the engine bearings.

- Proper lubrication of different parts of the crankshaft.

- Prevent the engine oil from mixing with fuel or coolant.

- Appropriate oil supply to the engine according to the manufacturer’s instructions.

- Avoid using oil that contains debris and other contamination.

- Prevent the engine from overheating.

- Routine maintenance and inspection of the engine.

- Use a crankshaft made of excellent and high-quality material.

- Change the oil filter, engine oil, and oil cooler on time.

- Properly check the shaft before its installation.

- Prevent the crankshaft from mechanical overloading through water hammer, abnormal combustion, etc.

completely informative for upcoming engineers