It has been said, over and over again, that there is NO replacement for displacement. A time-honored tradition, generations of gearheads have always embraced this bigger-is-better theme. What this simple statement implies is that, if a 350-inch motor is good, then a Texas-sized 400-incher must be even better, right?

There is some truth to this motto, as increased displacement will generally yield increased output, but this assumes a similar state of tune.

What we mean by state of tune is that not every 400 inch motor makes more power than every 350 inch motor. If the two motors sport the same heads, cam, and intake—the bigger-is-better displacement theory will generally hold true. If, however, the combinations differ, all bets are off.

Even if we ignore the possible exceptions to the displacement rule, I think we might well have found not only a replacement for displacement, but possibly even a more affordable alternative. Building a bigger (Stroker) motor is never cheap, but adding something as simple as a Sniper nitrous system from NOS is not only inexpensive, but plenty powerful as well.

Excuse the performance pun, but the Sniper System might just be the proverbial Cheap Shot.

The Sniper Nitrous System Kit

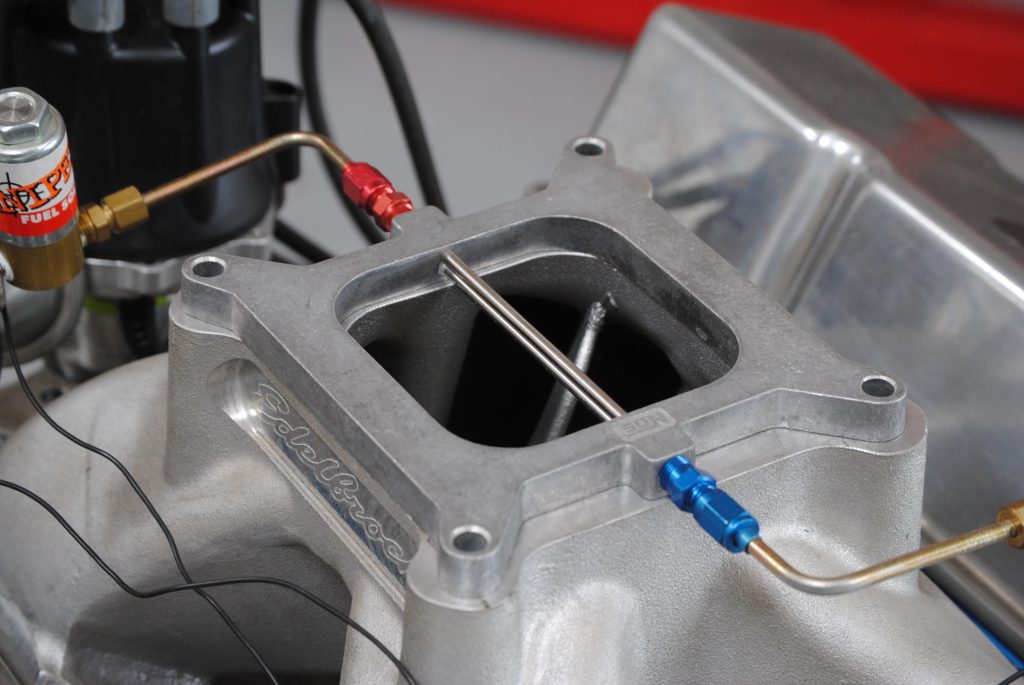

According to NOS, the Sniper nitrous oxide system was designed to offer safe and reliable performance at an affordable price. Like more expensive nitrous systems, the Sniper kit came complete and ready to install on any 4-barrel Holley carb flange. The kit (PN NOS-07001NOS) included the big stuff, namely the bottle, nitrous plate, and solenoids. The kit also featured smaller components, like the bottle mounts, arming and activation switches, and all the wiring and clamps to complete the installation.

Like high-end kits, the affordable Sniper system offered adjustable power levels. Using supplied jetting, the Sniper kit offered gains ranging from 100 to 150 horsepower—and who among us couldn’t use an extra 100 to 150 horsepower?

It is important to note that the nitrous bottles are shipped empty, and must be first filled at a local nitrous filling station prior to use.

Once installed, the Sniper system is ready to take a shot at some serious performance. While all of this sounded perfect on paper (it always does), naturally we wouldn’t rest until we put one of the Sniper systems to the test.

Quick, get that small block up on the dyno!

Notes on Making Power with a Nitrous System

One of the great things about nitrous oxide is that it is an equal opportunity employer, meaning it will add the desired power level to any combination. If you supply the 100 hp jetting, the nitrous doesn’t care if you install the system on a stock, mild, or fully built motor. When you push the button, the nitrous system does the rest.

Of course, like all power adders, it is up to you to ensure that the necessary safety precautions are observed—for nitrous, the most critical precaution is to retard the ignition timing.

Running nitrous assumes your motor is in good running condition and that you have a fuel pump capable of keeping pace with the additional fuel flow and power output. Contrary to the nonsense you see on the big (and small) screen, nitrous is perfectly safe even for stock motors. Just take care not to get greedy and start thinking your stock motor would be perfectly happy with an extra 200 hp, 250, or even 300 horsepower (trust us, it won’t be).

Word of advice on a stock motor: Leave those big-boy jets at home!

The Small Block Chevy Nitrous Test Engine

To illustrate the gains offered by the Sniper system, we installed one on Westech’s “Gladiator 2” test mule.

Starting out life as a 372 inch Dart SHP short block, the trusty small block Chevy had seen literally thousands of dyno runs, testing everything from heads, cams, and intakes to this Sniper NOS system.

In its latest configuration, the Dart SHP short block was finished up with a COMP XFI cam, AFR 195 Competition Eliminator cylinder heads, and an Edelbrock Super Victor intake.

The healthy COMP hydraulic roller cam offered a 0.584/0.579 lift split, a 242/248 degree duration split, and 113 degree LSA.

The cam was teamed with the Competition version of the AFR Eliminator heads. The CNC-ported heads offered 300+ cfm flow numbers capable of supporting over 600 horsepower, while the Edelbrock Super Victor intake ensured plenty of flow to the AFR heads and COMP cam.

Also run on the 372 inch test mule was a 950 Ultra HP Holley Carburetor, MSD billet distributor, and Meziere electric water pump.

The Dyno Results

Run in naturally aspirated trim, the small block Stroker produced 533 hp at 6,800 rpm and 466 lb.-ft. of torque at 5,300 rpm. After engaging the Sniper NOS system with 100 hp jetting, the peak numbers jumped to 652 hp and 563 lb.-ft. of torque.

We took the liberty of heating the bottle (the right way with a bottle heater) to get bottle pressure to 900 psi and leaned out the mixture by dropping the fuel pressure slightly to the fuel solenoid. There was an additional 50 hp left in the Sniper kit, but for now, we were plenty happy giving our small block the proverbial Cheap Shot.

Graph: Sniper NOS SBC Test: NA vs. NOS (100 hp Shot)

Comments