Abstract

The transparent flexible SnO2:Mo/Ag/SnO2:Mo (MTO/Ag/MTO) triple-layer film was prepared based on co-sputtering at room temperature for the first time. The optimization of the MTO layer thickness on the optical and electrical properties of the triple-layer films was investigated and the bending stability was verified by bending test. It was found that the visible light transmittance of the triple-layer film increases first and then decreases with the increase of MTO layer thickness, which indicates that the MTO layer thickness plays an important role in optimizing the visible light transmittance of the triple-layer film. Also, as the thickness of the MTO layer increases, the triple-layer film carrier concentration decreases and the sheet resistance increases. Therefore, the triple-layer film with excellent properties was obtained via the optimization of the MTO layer thickness to 40 nm, which has a maximum figure of merit of 2.0 × 10–2 Ω−1, a high visible light transparency of 82% and a low sheet resistance of 6.9 Ω/sq. Meanwhile, the prepared triple-layer film also has excellent mechanical flexibility (curvature radius R ≥ 4 mm, and the number of bending times is 10,000).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, transparent flexible displays have attracted wide attention due to their advantages of portability, intelligence and excellent visual experience. Therefore, the research on electrodes in transparent flexible thin film transistors (TFT) faces great challenges. In traditional TFTs, the electrodes are mostly metal electrodes with excellent electrical properties (such as Al, Mo, Ti, Ni / Ti, etc.) [1,2,3,4,5,6], but lower light transmittance of metal electrodes in the visible light range is not suitable for transparent TFT. Although some researchers have used indium tin oxide (ITO) transparent conductive films for TFT electrodes [7, 8], ITO films often require a high annealing process (> 150 ℃) in order to obtain a low resistivity [9,10,11,12,13]. Obviously, the high-temperature annealing process is still insufficient for electrodes in flexible TFT. In addition, indium-containing materials are not only costly but also causing environmental pollution [14, 15]. Therefore, the key to promote the field of transparent flexible display is to develop a transparent flexible conductive electrode that can be fabricated at low temperature or even room temperature, with strong mechanical flexibility, high visible light transparency, and low sheet resistance.

Recently, oxide/metal/oxide (OMO) structure film become a new research direction for transparent conductive electrodes due to their excellent properties, including high visible light transparency, low sheet resistance, enhanced flexibility, low cost, and room temperature preparation [16,17,18]. At present, the oxide layer materials used for OMO structure usually include ITO [19,20,21], zinc oxide (ZnO) [22,23,24], indium zinc oxide (IZO)[25], Sb doped SnO2 (ATO)[26], Tin oxide (SnO2) and so on [27, 28]. Among them, SnO2 as a functional material, has attracted much attention due to its high visible light transparency, low preparation cost and nontoxic [29,30,31]. Interestingly, it has been reported that Mo6+ doped SnO2 film has higher visible light transparency and lower resistivity than undoped SnO2 film [32]. Therefore, an approach combining the advantages of both OMO structure and MTO film has the potential to exploit a low-cost transparent flexible electrode with low sheet resistance and high visible light transparency at room temperature.

In this paper, transparent and flexible MTO/Ag/MTO films were designed and prepared based on co-sputtering at room temperature by combining the advantages of both OMO structure and MTO films. The optimization of MTO layer thickness on the optical and electrical properties of the triple-layer film was studied, and the bending stability of the triple-layer film was verified by bending test experiments.

2 Experimental procedure

MTO/Ag/MTO transparent flexible conductive triple-layer film was fabricated by co-sputtering deposition system at room temperature (schematic view as shown in Fig. 1). Firstly, bottom MTO films with different thicknesses (e.g. 16 nm, 24 nm, 32 nm, 40 nm, 48 nm, and 56 nm) were prepared on Polyethylene Terephthalate (PET) flexible substrates using RF and DC co-sputtering. Among them, the sputtering power of tin oxide target and molybdenum target were 46.8W and 9.2W, respectively, and the sputtering pressure of argon gas was 0.5pa during the sputtering process. Secondly, an 8 nm-thick intermediate Ag layer, which was just enough to form a continuous Ag film [33], was deposited by DC sputtering. The sputtering power of Ag target (99.99% purity) was 75.4 W, and the sputtering pressure of argon gas was 0.5 pa. Finally, the top MTO layer was deposited on the Ag layer, which is the same as the bottom MTO film.

The thickness of the film was measured with a stylus profilometer (Bruker). Mo content was measured by X-ray photoelectron spectroscopy (XPS, Thermo Scientific K-Alpha). The crystalline structure of the film was analyzed by X-ray diffraction (XRD, Evolution 220). The four-point probe (FPP, RTS-8) and UV–visible spectrophotometer (UV, 2450) were used to test the sheet resistance and optical transmittance of the film, respectively. The Hall mobility and electrical resistivities of the films were measured by a Hall effect measurement system (PPMS-9).

3 Results and discussions

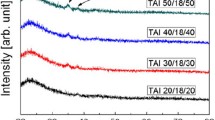

Figure 2 shows the corresponding XRD patterns of Ag (8 nm) film, MTO (40 nm)/Ag (8 nm)/MTO (40 nm) triple-layer film and MTO (40 nm) film, respectively. As shown in Fig. 2, no obvious diffraction peak appears in the XRD pattern of the MTO film, suggesting that the MTO layers are amorphous. A strong Ag (111) diffraction peak at 38.26° and a relatively weak Ag (200) at 44.44° appear in the XRD spectra of both Ag films and triple-layer films. This indicates that the intermediate Ag layer has a polycrystalline structure, and the preparation of the MTO layer has almost no effect on the structure of the intermediate Ag layer.

Figure 3 shows the Mo3d X-ray photoelectron spectroscopy (XPS) spectrum of MTO films. As shown in Fig. 3, the Mo3d5/2 and Mo3d3/2 peak positions in the MTO film are located at 232.3 eV and 235.8 eV, respectively, corresponding to the M–O bond in MoO3 [34]. This reveals that Mo atoms, as an additive to the SnO2 films, were well combined with oxygen atoms, and the atomic percentage content of the Mo in MTO thin films is 0.6 at.%. Also, based on the peak fitting of XPS raw data, it is found that the doped Mo ions in the SnO2 film are in the mixed valence states of Mo6+ (peaks at binding energies of 232.7 eV and 235.8 eV) and Mo5+ (peaks at binding energies of 231.8eVand 234.3 eV) [32], and Mo6+ dominates in the derived peak of the spectra, as shown in Fig. 3.

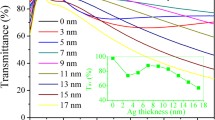

Figure 4a and b show the optical transmittance spectra of the MTO film and the MTO/Ag/MTO film as a function of the thickness of the MTO layer, respectively. To quantitatively analyze the effect of the MTO layer thickness on the optical properties of MTO monolayer film and MTO/Ag/MTO triple-layer films, the average transmittance of all monolayer film and triple-layer film samples in the visible light range (400–700 nm) was calculated by using the following relationship [22], as shown in Fig. 4c.

where T(λ) is the transmittance and V(λ) is the photopic luminous efficiency function defining the standard observer for photometry. The average optical transmittance of MTO monolayer films decreases from 99.2 to 95.5% as the MTO films thickness increases from 16 to 56 nm. This may be because the light absorption of MTO films increases with thickness. As the thickness of the MTO layer increases from 16 to 56 nm the average optical transmittance of triple-layer films in the visible light range increases from 47 to 82% and then decreases to 78%. And the average transmittance of the triple-layer film in the visible range reaches a maximum of 82% when the thickness of MTO layer is 40 nm. Generally, the reasons that affect the transmittance of OMO triple-layer films often involve the following two aspects. On the one hand, according to Fresnel theory, the reflectivity of the triple-layer film to visible light can reach a very low value based on the adjustment of the oxide layer thickness of the OMO triple-layer film with the fixed conditions of the OMO film for each layer material, which can effectively improve the transmittance of the OMO triple-layer film to visible light [35]. On the other hand, based on the selection of film materials constituting each layer of the OMO film, the adjustment of film thickness, and the optimization of film surface flatness, the absorption of the triple-layer film to visible light can be reduced by suppressing surface plasmon (SP) coupling between the oxide/metal interface [36], thereby improving the transmittance of the triple-layer film. In this study, the MTO/Ag/MTO triple-layer film showed the highest visible light transmittance only by adjusting the MTO layer thickness to 40 nm with the fixed conditions of the oxide layer material (MTO), the metal layer material (Ag) and its thickness, and the film forming process. This may be due to the best comprehensive effect of the triple-layer film on the reflectivity of visible light and the suppression of SP coupling between the MTO/Ag interface when the MTO layer is 40 nm.

a Transmittance spectra of MTO film b transmittance spectra of MTO/Ag/MTO triple-layer films with the different MTO layer thickness, where the inset shows a representative physical image of the triple-layer film with the MTO layer thickness of 40 nm. c The average transmittance in the visible range of MTO films and MTO/Ag/MTO films as a function of the MTO layer thickness (the measured result for the transmittance spectra is not including substrate)

Figure 5 shows the sheet resistance, effective resistivity, and free carrier concentration of MTO/Ag/MTO triple-layer film as a function of the MTO layer thickness. As shown in Fig. 5, as the MTO layer thickness increases from 16 to 56 nm, the sheet resistance of triple-layer film increases from 5.6 to 8.3 Ω/sq, and the effective resistivity increases from 1.2 × 10–4 to 2.7 × 10–4 Ω·cm. The increases in sheet resistance and effective resistivity are due to the decrease of free carrier concentration [23, 37], as shown in Fig. 5. The best combination of high electrical and optical properties of triple-layer films can be evaluated by the figure of merit (FOM), which is described by Haacke as follows [38].

where φ is the FOM value, Tav is the average transmittance in the visible light range, and RS is the corresponding sheet resistance of the sample. Figure 6 shows the FOM value of triple-layer film as a function of the thickness of the MTO layer. As shown in Fig. 6, when the thickness of the MTO layer is 40 nm, the triple-layer film has the highest FOM value of 2.0 × 10–2 Ω−1, which has the optimum optical and electrical comprehensive performance (Tav = 82%, Rs = 6.9 Ω/sq), and it is worth mentioning that its electrical performance is comparable to that of Ag monolayer film (Rs = 4.7 Ω/sq). In addition, undoped Mo-doped SnO2 (40 nm)/Ag/SnO2 (40 nm) triple-layer films were prepared using the same experimental conditions as those of MTO (40 nm)/Ag/MTO (40 nm) with the highest FOM values to further validate the effect of Mo doping on the properties of the triple-layer films. It is found that the average transmittance of MTO/Ag/MTO film in the visible light range (82%) is higher than that of SnO2/Ag/SnO2 film (50%), as shown in Fig. 7, and the sheet resistance of MTO/Ag/MTO film (6.9 Ω/sq) is lower than that of SnO2/Ag/SnO2 film (14.5 Ω/sq).This indicates that the addition of Mo in SnO2 can effectively improve the optical and electrical properties of SnO2 (40 nm)/Ag/SnO2 (40 nm) triple-layer films.

To further investigate the bending stability of the MTO/Ag/MTO triple-layer film, the triple-layer film with a MTO layer thickness of 40 nm was selected for bending tests. Figure 8 shows the electrical and optical properties of MTO/Ag/MTO triple-layer film as a function of bending times at the radius of curvature (R) of 6 mm, 4 mm and 2 mm, respectively. As shown in Fig. 8a and b, the sheet resistance of triple-layer film increases only by 0.3 ± 0.1 Ω/sq and remains basically stable after 10,000 bending cycles with a radius of curvature of 6 mm and 4 mm, respectively. However, when the bending curvature radius of the triple-layer film is reduced to 2 mm, the sheet resistance nearly doubled (from 6.9 to 14 Ω/sq) after 10,000 times bending, as shown in Fig. 8c, which may be due to the generation of slight mechanical cracks. In addition, the visible light transmittance of the triple-layer film remains basically unchanged at 82% in the bending test, as shown in Fig. 8d–f. Therefore, the MTO/Ag/MTO transparent flexible films have excellent mechanical flexibility (R ≥ 4 mm, and the number of bending times is 10,000) and have great potential to be used in transparent flexible electronic devices.

Changes in the electrical properties of MTO/Ag/MTO triple-layer films by bending down 10,000 times at the radius of curvature of a 6 mm, b 4 mm and c 2 mm, respectively. Changes in the optical properties of MTO/Ag/MTO triple-layer films based on 10,000 times bending tests at the radius of curvature of d 6 mm, e 4 mm and f 2 mm, respectively

Table 1 shows the comparison of reported oxide/Ag/oxide triple-layer films. As shown in Table 1, the electrical properties of MTO/Ag/MTO triple-layer films are comparable to those of reported indium-containing triple-layer films (e.g., IZO/Ag/IZO, ITO/Ag/ITO), and they have higher visible light transparency. Moreover, MTO (SnO2:Mo) oxides also have the advantages of low cost and environmental protection compared with indium-containing oxide materials. It is worth mentioning that, compared with the reported indium-free triple-layer films (e.g., ZnO/Ag/ZnO, AZO/Ag/AZO), the MTO/Ag/MTO triple-layer film developed in this study not only exhibits comparable visible light transmittance but also has lower sheet resistance and presents better electrical properties. In addition, there are few reports on the bending stress stability based on an oxide/Ag/oxide triple-layer film, which needs to be further studied. The novel MTO/Ag/MTO transparent conductive films developed in this study also exhibit excellent bending stress stability (R ≥ 4 mm, and the number of bending times is 10,000). Therefore, this work provides a new way to develop flexible transparent electrodes with high performance, low cost and 1ow temperature (under room temperature).

4 Conclusion

In this work, the transparent flexible conductive MTO/Ag/MTO triple-layer films were successfully prepared based on co-sputtering at room temperature for the first time. The optical and electrical properties of the triple-layer films were optimized by adjusting the MTO layer thickness, and the bending stability of the triple-layer films was verified by bending tests. The results show that as the MTO layer thickness increases, the visible light transmittance of the triple-layer films in the visible light range increases and then decreases, since the MTO layer thickness has an important effect on optimizing the visible light transmittance of the triple-layer film. Furthermore, as the MTO layer thickness increases, the carrier concentration of the triple-layer film decreases, and its sheet resistance and effective resistivity gradually increase. The triple-layer film exhibits the best performance by optimizing the MTO layer thickness to 40 nm, with a high visible transmittance of 82%, a low sheet resistance of 6.9 Ω/sq, and a maximum FOM value of 2.0 × 10–2 Ω−1. Moreover, the electrical and optical properties of the triple-layer film with the MTO layer thickness of 40 nm show excellent mechanical flexibility (curvature radius R ≥ 4 mm, and the number of bending times is 10,000). Therefore, MTO/Ag/MTO triple-layer films are expected to be used as electrodes in transparent flexible TFT to promote the development of transparent flexible displays.

Data availability

Data underlying the results presented in this paper are not publicly available at this time but maybe obtained from the authors upon reasonable request.

References

A. Baltakesmez, B. Güzeldir, Appl. Phys. A 129, 2 (2023)

W. Yang, H. Yang, J. Su, X. Zhang, Vaccum 205, 111419 (2022)

A. Kumar, S.Y. Lee, Microelectron. Eng. 261, 111794 (2022)

W. Pan, X. Zhou, Y. Li, W. Dong, L. Lu, S. Zhang, Mater. Sci. Semicond. Process. 151, 106998 (2022)

C.X. Huang, J. Li, Y.Z. Fu, J.H. Zhang, X.Y. Jiang, Z.L. Zhang, Q.H. Yang, J. Alloys Compd. 681, 81–87 (2016)

A. Panca, J. Panidi, H. Faber, S. Stathopoulos, T.D. Anthopoulos, T. Prodromakis, Adv. Funct. Mater. 33, 20 (2023)

X. Yin, D. Lin, W. Zhong, Y. Chen, G. Li, Y. Li, R. Chen, Solid State Electron. 208, 108726 (2023)

M.E. Rivas-Aguilar, N. Hernandez-Como, G. Gutierrez-Heredia, A. Sánchez-Martínez, M.M. Ramirez, I. Mejia, M.A. Quevedo-López, Curr. Appl. Phys. 18, 7 (2018)

E.R. Ollotu, J.S. Nyarige, N.R. Mlyuka, M.E. Samiji, M. Diale, J. Mater. Sci. Mater. Electron. 31, 19 (2020)

S. Song, T. Yang, J. Liu, Y. Xin, Y. Li, S. Han, Appl. Surf. Sci. 257, 16 (2011)

A.H. Ali, Z. Hassan, A. Shuhaimi, Appl. Surf. Sci. 443, 544–547 (2018)

H. Khachatryan, D.J. Kim, M. Kim, H.K. Kim, Mater. Sci. Semicond. Process. 88, 51–56 (2018)

J.H. Park, C. Buurma, S. Sivananthan, R. Kodama, W. Gao, T.A. Gessert, Appl. Surf. Sci. 307, 388–392 (2014)

S. Seong, Y.C. Jung, T. Lee, I.S. Park, J. Ahn, Mater. Sci. Semicond. Process. 79, 14–19 (2018)

N. Meshram, C. Loka, K.R. Park, K.S. Lee, Mater. Lett. 145, 120–124 (2015)

S.J. Oh, S. Lee, K.C. Choi, J.H. Kwon, T.S. Kim, J. Mater. Chem. C 11, 22 (2023)

K. Sivaramakrishnan, N.D. Theodore, J.F. Moulder, T.L. Alford, J. Appl. Phys. 106, 6 (2009)

H. Salmaniannezhad, H. Salmaniannezhad, R. Zarei-Moghadam, M. Khani, M. Ardani, B. Shokri, Progress Phys. Appl. Mater. 3, 2 (2023)

H. Wang, C. Tang, Q. Shi, M. Wei, Y. Su, S. Lin, M. Dai, Ceram. Int. 47, 6 (2021)

H. Ghasemi, M.H. Mozaffari, R. Moradian, N. Ghobadi, Mater. Sci. Semicond. Process. 149, 106853 (2022)

S.H. Park, S.J. Lee, J.H. Lee, J. Kal, J. Hahn, H.K. Kim, Org. Electron. 30, 112–121 (2016)

M. Rabizadeh, M.H. Ehsani, M.M. Shahidi, Sci. Rep. 12, 1 (2022)

S.Y. Park, S.Y. Lee, Carbon Lett. 33, 4 (2023)

M. Rabizadeh, M.H. Ehsani, Ceram. Int. 48, 11 (2022)

Y.C. Kim, S.J. Lee, I.K. Oh, S. Seo, H. Kim, J.M. Myoung, J. Alloys Compd. 688, 1108–1114 (2016)

M. Wu, H. Zheng, X. Li, S. Yu, Ceram. Int. 46, 4 (2020)

L. Song, C. Wu, S. Yu, X. Wang, Mater. Lett. 312, 131683 (2022)

S. Yu, W. Zhang, L. Li, D. Xu, H. Dong, Y. Jin, Thin Solid Films 552, 218–224 (2014)

M. Batzill, U. Diebold, Prog. Surf. Sci. 79, 2 (2005)

D.R. Sahu, J.L. Huang, Thin Solid Films 516, 2 (2007)

E.C. Nwanna, P.E. Imoisili, T.C. Jen, J. Mater. Res. Technol. 17, 102123 (2022)

T. Ma, M. Nikiel, A.G. Thomas, M. Missous, D.J. Lewis, J. Mater. Sci. 56, 28 (2021)

J. Szczyrbowski, A. Dietrich, K. Hartig, Sol Energy Mater. 16, 1 (1987)

D.O. Scanlon, G.W. Watson, D.J. Payne, G.R. Atkinson, R.G. Egdell, D.S.L. Law, J. Phys. Chem. C 114, 10 (2010)

P. Grosse, R. Hertling, T. Müggenburg, J. Non-Cryst. Solids 218 (1997).

R. Pandey, B. Angadi, S.K. Kim, J.W. Choi, D.K. Hwang, W.K. Choi, Opt. Mater. Express 4, 10 (2014)

Z.S. Yuan, C.C. Wu, W.C. Tzou, C.F. Yang, Y.H. Chen, Vacuum 165, 305–310 (2019)

G. Haacke, New figure of merit for transparent conductors. J. Appl. Phys. 47, 9 (1976)

S.W. Cho, J.A. Jeong, J.H. Bae, J.M. Moon, K.H. Choi, S.W. Jeong, N.J. Park, J.J. Kim, S.H. Lee, J.W. Kang, M.S. Yi, H.K. Kim, Thin Solid Films 516, 21 (2008)

T.H. Kim, B.H. Choi, J.S. Park, S.M. Lee, Y.S. Lee, L.S. Park, Mol. Cryst. Liq. Cryst. 520, 1 (2010)

V. Sharma, P. Kumar, A. Kumar, Surbhi, K. Asokan, K. Sachdev, Sol Energy Mat. Sol C 169, 122–131 (2017)

Y. Zhang, L. Wang, Z. Geng, D. Zhang, D. Wang, J. Liu, Q. Wang, Mater. Sci. Semicond. Process. 165, 107643 (2023)

Y. Sugimoto, K. Igarashi, S. Shirasaki, A. Kikuchi, Jpn. J. Appl. Phys. 55, 4S (2016)

Acknowledgements

This work was supported by National Natural Science Foundation of China (No.62064001), by GuiZhou Provincial Basic Research Program (Natural Science) (No. ZK[2021]238), by Science and Technology Personnel Planning Project of GuiZhou Province (YQK[2023]018), and by Science and Technology Planning Foundation of GuiYang City (No. [2021]43-2).

Author information

Authors and Affiliations

Contributions

Min Su: Investigation, Writing-Original Draft. Suheng Shi: Investigation. Jiarong Chen: Investigation. Dasen Ren: Methodology. Lan Yue: Conceptualization, Resources, Writing-Review & Editing, Funding acquisition, Project administration. Fanxin Meng: Conceptualization, Funding acquisition, Methodology.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, M., Shi, S., Chen, J. et al. Preparation and optimization of MTO/Ag/MTO transparent flexible film based on co-sputtering at room temperature. Appl. Phys. A 130, 406 (2024). https://doi.org/10.1007/s00339-024-07557-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-024-07557-w