——Shijun He, the father of Jintang screw and the founder of Zhoushan Jwell Screw & Barrel Co.,Ltd

Speaking of Jintang screw, Shijun He has to be mentioned. Shijun He is a diligent and innovative entrepreneur who is known as the “Father of Jintang Screw”.

In the mid-1980s, he poured his passion into a small screw, solved the processing problems of key parts of plastic machinery, and broke the technological monopoly of developed countries. He not only founded China’s first professional screw production enterprises, cultivated a number of outstanding entrepreneurs and technical backbone, but also made an industry chain, enriching the local people, and developing Jintang into the screw capital of China and the world screw processing and manufacturing center.

On 10th May, Shijun He passed away due to illness.

Today, let’s get to know Shijun He and remember the legendary entrepreneur with innovation, perseverance

“He has a pair of ‘patriotic and dedicated craftsman’s hands’, and walks the ‘innovation and entrepreneurship innovation road’.”

Dare to think and dare to do, he tireless pursuit of scientific and technological innovation.

The public has given Shijun He many honorary titles: the founder of China’s screw capital, China’s plastics machinery industry meritorious figures, China’s first tidal power generation ……

But he describes himself in this way: “I have always felt that I am an ordinary folk craftsman, a mechanical mechanic, with a pair of ‘patriotic and dedicated craftsman’s hands’, and a life-long walk of ‘innovation and entrepreneurship innovation road’. “

He once said: “I like to do exploratory things.” Indeed, his legendary life is full of vivid chapters of willingness to study and dare to innovate.

As early as when he was a teenager, Shijun He already showed extraordinary talent and creativity.

In 1958, during his senior year at Zhoushan Middle School, he was keen on researching aviation engines and wrote a paper on “Changing Aircraft Turbo Engines into Turbofans”, which was sent to the head of the Power Department of the Beijing University of Aeronautics and Astronautics and was highly praised.

On the basis of his high school studies, Shijun He took 24 university courses by correspondence at Zhejiang University, majoring in mechanical engineering, and with the support of his teachers, he developed wind turbines. He designed the drawings, made the parts, assembled and debugged by himself, and finally successfully manufactured the first wind turbine in Zhoushan with a power of 7KW, which was successfully generating electricity at the top of Ao shan Mountain in Dinghai Town at that time.

This was Shijun He’s first bold attempt in the field of engineering.

In 1961-1962, China was caught in the dilemma of oil shortage, and power plants were shut down because they could not generate electricity. Shijun He visited several islands in Zhoushan and found that the ocean currents were flowing at a speed of more than 3 meters per second. According to this speed, there are dozens of harbor channels in Zhoushan with the possibility of developing tidal current power, and the power available for development and utilization is more than 2.4 million kilowatts. He keenly perceived that it was a good time to invent tidal current power generation.

Shijun He wrote a report on the topic of “Developing Zhoushan tidal current power generation to solve the problem of electricity consumption”, which was emphasized by the Zhoushan Regional Science and Technology Commission. A leader suggested that whether we can first do a “small principle model” test to prove the principle of feasibility and then demonstrate the specific development of the problem.

The team did what they said. Shijun He led a team that chose the Xihoumen waterway to carry out the test. They rented a ferry, fixed two turbines on the side of the ship, and lowered them into the sea. In the following three months, Shijun He’s team debugged and tested the turbines again and again, and tackled the problem again and again.

“‘It’s good to be a captain of a ship, but it’s hard to be at Xihoumen’. The current in that area is fast, and there are strong whirlpools, so it’s not easy to do the test.” More than 40 years later, Shijun He’s apprentice Henneng Xu still clearly remembers a dangerous situation.

That day, the wind and waves were strong. The chain connecting the ferry to the pier rubbed against the rocks so many times that it snapped. The whole ferry lost its balance at once and rocked violently with the waves. “At that time there was a huge whirlpool not far from us, thanks to a wave hit, the boat changed direction, otherwise the consequences are unimaginable.” After getting off the shore, Heneng Xu realized that their clothes have long been soaked with cold sweat.

Through a difficult, crack a problem. March 17th 1978, the day before the first National Science Conference, Shijun He ushered in an important moment in his life: as the turbine began to run, the generator rumbled, hanging on the ferry dozens of 100-watt power lights then lit up, the ship and the shore suddenly rang cheers. Tidal power generation was successful!

“When the test was successful, the local people set off firecrackers and came out of their homes to the harbor to watch.” That scene also stuck in the mind of Shijun He’s second son, Haichao He. “I watched my father leading a group of young people, forgetting about sleep and food and engaging in scientific research, and also secretly resolved in my heart that I would become like him when I grew up.”

Three years later, a group of domestic experts went to Zhoushan to watch tidal power generation on site. Professor Cheng of Huazhong University of Science and Technology, a famous expert in hydraulic machinery, pointed out, “We have not yet seen any reports of electricity generated by tidal current in the world, but Shijun He is definitely the first person to generate electricity by tidal current in China.”

Shijun He from the test to get a lot of data, has written “tidal current power generation” and other papers, were published in the provincial and national professional magazines.In the relevant professionals’ view, the results of Shijun He’s exploration is the cornerstone of the development of China’s tidal current energy industry, which not only verifies the huge potential of tidal current energy as a clean, renewable new energy, but also opens a new chapter in China and even the world’s utilization of marine energy.

“A screw is sold at such a high price, it’s too bullying to the Chinese people.”

Self-improvement, he successfully developed the first screws in Zhoushan.

Reform and opening up for more than 40 years, China has made remarkable achievements and become a manufacturing power with a complete range of industrial categories. These achievements have been made possible by generations of craftsmen’s work philosophy of excellence and a high sense of responsibility for the development of the nation.

Shijun He’s figure is among the star-studded group of Chinese craftsmen.

In 1985, during the wave of state-owned enterprise reform, Shijun He followed the pace of the times, keenly captured the huge potential of China’s plastics industry, and resolutely resigned to start his own factory.

Shijun He was invited to a national seminar on the development and utilization of marine energy held by the State Science and Technology Commission in Yantai, Shandong Province. Shijun He was invited to go to the seminar, On the way, he met an engineer from Shanghai Panda Cable Factory who was going to Qingdao to participate in the International Plastic Machinery Exhibition.

It was this meeting that changed Shijun He’s life.

At that time, China’s plastics industry was developing rapidly, but encountered the developed countries on the complete sets of plastic machine equipment and core components of various plastic machine screws to implement the technological monopoly. A set of production of chemical fiber Vc403 screw to be sold to 30,000 U.S. dollars, the diameter of 45 mm BM-type screw sold to 10,000 U.S. dollars.

“To the exhibition, I was shocked. A screw was sold at such a high price, it was really bullying the Chinese. Even if you use silver as a material, it doesn’t have to be so expensive. If I were to do it, it wouldn’t cost more than a few thousand dollars.” Shijun He lamented.

When he heard this, Engineer Zhang from Shanghai Panda Cable Factory asked, “Can you really do it?” Shijun He replied confidently, “Yes!” Engineer Zhang and Mr. Peng then expressed their support for Shijun He’s trial production of the screw, and they produced the drawings.

This was a trial that spelled out the aspirations of the country’s people. Shijun He went all out.

With the support of his wife, Zhi’e Yin, he borrowed 8,000 CNY from friends and relatives as start-up capital and began trial production.

After nearly half a month of day and night, Shijun He in the existing lathe to complete the “special screw milling machine” design and development and transformation, and then spent 34 days, the trial production of 10 BM-type screws.

The screws were made, but the performance was not good enough? Shijun He took the first batch of 10 screws from Ligang on the road of delivery. After arriving at Shanghai Shipu Terminal early the next morning, he transported the screws to Shanghai Panda Cable Factory in 5 shipments.

“We said we would deliver the products in 3 months, but it took less than 2 months for them to be ready.” When they saw Shijun He, Engineer Zhang and Mr. Peng were full of surprise. When they opened the packing box, the shiny screw was introduced to their eyes, and the engineers shouted “yes” again and again.

After sending the production department for quality inspection and measurement, the dimensions of the 10 screws made by Shijun He met the requirements of the drawings, and the physical and chemical properties of the products were consistent with those of the imported screws. Hearing this news, everyone hugged each other and cheered to celebrate.

The next morning, Shijun He returned home. His wife looked at him with empty hands and comforted him by saying, “The screw is lost in the Huangpu River? It doesn’t matter, we can set up a stall to repair bicycles and sewing machines, and we can still get by.”

Shijun He told his wife with a smile, “They took all the screws. They sold them for 3,000 yuan each.”

After that, Shijun He used the first bucket of gold he earned to continue to add equipment and personnel to devote himself to screw manufacturing, and also registered the trademark “Jin Hailuo” with the State Trademark Office.

With the support of the deputy commissioner of Zhoushan District Administration, Shijun He registered “Zhoushan Donghai Plastic Screw Factory”, which is a school-run enterprise of Donghai School. This is also China’s first professional production of screw barrel manufacturers. Since then, the era of China’s professional screw manufacturing curtain slowly opened.

Donghai Plastic Screw Factory produces screws of good quality and low prices, orders continue to flow. The situation that only western countries and large state-owned military enterprises could produce screws and barrels was completely broken.

By the end of the 1980s, Shijun He owned nearly 10 enterprises in Zhoushan, Shanghai and Guangzhou. 2020, the total output value of these enterprises reached 6 billion yuan, with profits and taxes of more than 500 million yuan, and became the “leader” in the fields of plastic extrusion and chemical fiber machinery.

After founding the factory, Shijun He also trained many apprentices. He laughingly called his factory the “Whampoa Military Academy” of the screw industry. “I encourage them to use technology to start a career. Every one of my apprentices can stand on their own.” Shijun He said. Shijun He said that at that time, Jintang produced a single process per person in the form of a family workshop, and finally, the larger enterprises were the gatekeepers of sales, and then distributed compensation to the laborers of each process.

This approach became the main production method of Jintang screw barrels at that time, and also led the people of Jintang towards the road of entrepreneurship and wealth.

Shijun He once said, “Some people ask me why I tell others about my technology when I have researched it with great difficulty. I think technology is a useful thing, and it makes sense to lead people to get rich together.”

After nearly 40 years of development, Jintang has become the largest production and export base of plastic machine screws in China, with more than 300 plastic machine screw enterprises, and the annual production and sales volume accounting for more than 75% of the domestic market, which is regarded as the “Screw Capital of China”.

“He was a loving father and a mentor to us.”

Remembering, Relaying, Inheriting the Craftsman Spirit, Serving the Development of Society

When he learned the sad news of his father’s death, Haichao He was attending a exhibition in the United States. He rushed back to Zhoushan immediately.

On the way back, his father’s voice and smile constantly lingered in Haichao He’s mind. “I remember when I was a child, as long as he was free, he would take us to keep bees, to the wild mountain climbing and prospecting. He also took us with him to do farm work and assemble tube radios and transistor radios ……”

In Haichao He’s memories, his father often drew designs alone late into the night, and he always waited until the end to accompany him home. “The reward was being able to drink steaming hot sweet soybean milk in the middle of the night, sometimes with a doughnut. That flavor is something I remember clearly to this day.”

“He was a loving father and even more of a mentor in our lives.” Haichao He recalled that as a child, his father would always teach their three brothers the principles of pulley sets, mechanical calculations of cantilever beams, and the principles of problems such as the vertical alignment of concrete beams, based on the principles of mechanics in textbooks. “This also made me believe from childhood that knowledge is power.”

While working as a maintenance clampman at Zhoushan Fisheries Company’s ship repair plant, Haichao He’s 2 masters had heard of Shijun He’s name as well as his diesel engine skills. “This greatly inspired my passion for work. My father vividly interpreted the philosophy of life that ‘Having a wealth is not as good as having a skill.’, which also profoundly influenced my entrepreneurial path.” Haichao He said.

In 1997, Haichao He took over his father’s baton and founded Shanghai bien Machinery Co. Ltd. Today, Today, Jwell Machinery has more than 30 subsidiaries and has ranked first in China’s plastic extrusion industry for 13 consecutive years .

“He is an admirable and outstanding entrepreneur.” In the heart of Dongping Su, executive vice president of the China Plastics Machinery Industry Association, he has been firmly remembering several stories about his time with Shijun He.

In 2012, Dongping Su led a team to participate in the NPE exhibition in the U.S.. Shijun He was the oldest team member traveling with him at that time. Along the way, he shared his experiences in technical research, and talked about his experience in beekeeping after retirement and the papers he had written. The team members respected and liked this optimistic old man from the bottom of their hearts.

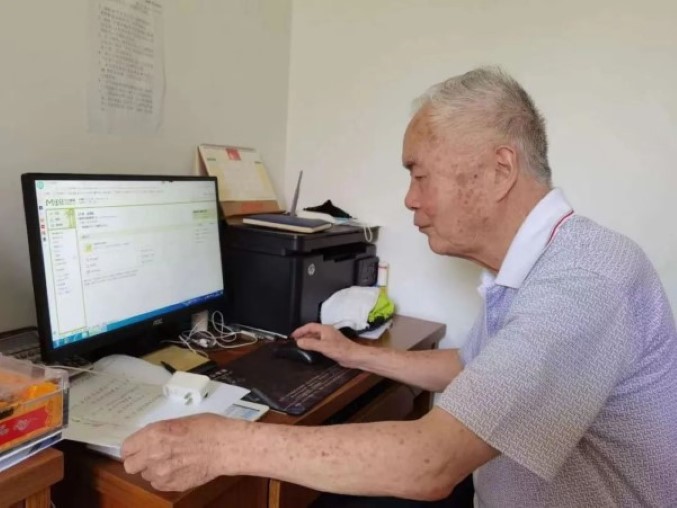

Two years ago, Dongping Su and Shijun He traveled together from Zhoushan to Jwell Machinery Haining factory. during the more than three-hour journey, Shijun He told her about his thoughts on how to mass-produce graphene with a plasticizer. “The day before, he had carefully drawn out the idea diagram, looking forward to the day when he could turn his wish into reality.”

“This meritorious figure in China’s plastics machinery industry is not greedy for enjoyment, and at the age of more than 80 years, he is still full of scientific research and innovation, which is really touching!” Dongping Su also firmly in mind, to complete one of his commission: the submarine can be simulated with fish lift to reduce the principle of noise, informed the national defense research institutions.

Deep in the heart, never forget. Over the past few days, Haichao He and relatives received from the China Plastics Machinery Industry Association, China Plastics Processing Industry Association, the Shanghai Zhoushan Chamber of Commerce, Jintang Management Committee and other industry associations, departments and colleges and institutes of condolence letter. City leaders, as well as government departments, heads of related organizations, entrepreneurs, citizens, etc., have come to offer their condolences.

Shijun He’s passing also made waves on Jintang Island. “Grateful to Mr. He, who gave the people of Jintang a career to make a living.” Junbing Yang, general manager of Zhejiang Zhongyang Screw Manufacturing Co. Ltd, expressed his memorial to Shijun He.

“After the reform and opening up, Jintang people, in order to get rid of poverty, ran garment factories, woolen sweater factories, plastic factories, and overseas Chinese also came to run otter farms, sock factories, furniture factories, etc., all of which were quickly surpassed by foreign enterprises due to inconvenient logistics and high costs. Only Mr.He pioneered the screw barrel, in Jintang roots, branches and leaves, but also led to the development of tertiary industry. Every Jintang person has benefited a lot from Mr.He’s invention.” The relevant person in charge of the Economic Development Bureau of Jintang Management Committee said.

“Having experienced the vast sea,it is difficult to turn in to water.Apart from Mount Wu, there is no cloud can compare with.” One day in early May, the eldest son, Haibo He, and his mother, stood in front of Shijun He’s bed. Shijun He, who was on his deathbed, read the poem to his relatives with deep emotion and expressed his deep attachment to his wife.

“Throughout my life ,in one sentence. My love is as deep as the sea, touching to the heart” Haibo He said that his father was very grateful for everyone’s concern and help during his lifetime, has been fondly remembering beloved family and friends, remembering the good old days that could not bear to part with.

“Although the legendary story of Shijun He, the father of the Jintang screw, has come to an end, his spirit lives on.

The article is reprinted from “Zhoushan News Media Center”